Technology and Services

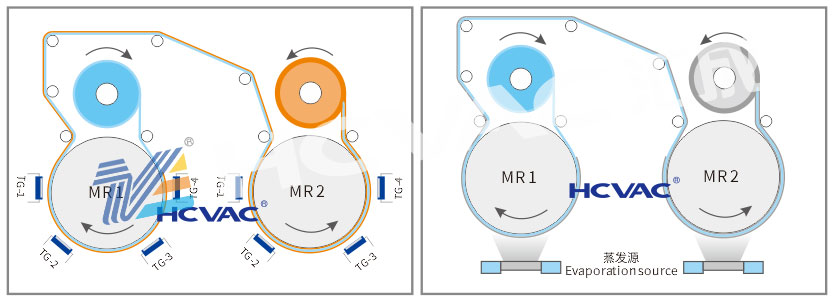

PVD web coating equipment that can complete PET/PP double side coating in one time, high density and strong adhesion metal film, high-precision roll to roll system, low tension control, special flattening effect of substrate, and achieve high-capacity batch production.

Ultra thin composite copper foil PVD RTR coating equipment:

Achieve thickness of 3.0~4.5 μ m. The surface of PET/PP plastic film with a width of 600 ~ 1650mm is coated with copper on both sides at one time, and the sandwich structure of "PVD copper polymer support layer PVD copper" is adopted. The process speed of the equipment is 0.5-30m/min.

Ultra thin composite aluminum foil PVD RTR coating equipment:

The thickness is 4.5~6.0 μ m. The PET/PP plastic film with a width of 600~1700 mm is coated with aluminum on both sides, and the sandwich structure of "PVD aluminum - polymer support layer PVD aluminum". The equipment and process speed is 30-100 m/min, overcoming the difficulty of large-scale rapid evaporation and deposition of thick aluminum film.

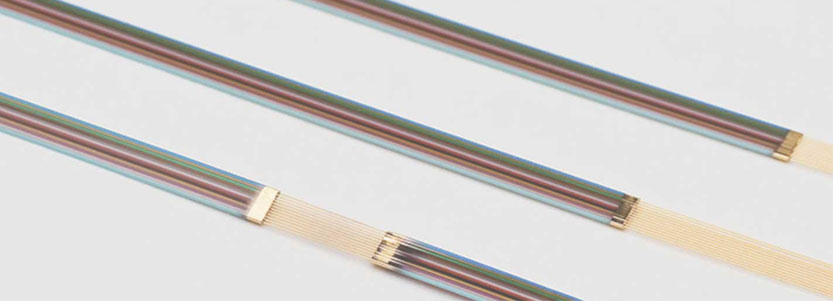

HCVAC can metalize your optical fibers with Titanium/Platinum/Gold by producing a single or multi-layer symmetrical metal coating on ends, mid spans or windows for use in hermetically sealed opto-electronic packages. our experts can also create radially symmetrical material stacks on a cylindrical rod or tube components. Features and benefits include:

- Low temperature deposition avoids damage of plastic on fibers.

- Coating has good uniformity around the entire fiber for accurate fiber alignments.

- Excellent adhesion strength resulting from a pre-clean step prior to coating.

- Load-locked system allows for coating of jacketed and connected components.

- Re-coating of fiber Bragg Gratings.

- Anti-Reflective and protected mirror coatings on polished ends.

Chromium plating is an ideal coating method to give products high mechanical properties. At the same time, it has attractive metal appearance and aesthetic impact, which increases the added value of products. Compared with traditional electroplating, uv-pvd combination is safer, more economical and more environmentally friendly. Therefore, traditional electroplating is gradually eliminated.

Using vacuum sputtering technology, harmful emissions are completely eliminated, and environmental friendly chromium plating is developed instead of electroplating. The process cycle is very fast, and its excellent performance is transformed into efficient and economical green production. Uv-pvd chromium plating process is environmentally friendly. It works at room temperature without water consumption and chemical discharge. By reducing production time, repetition cycle and minimizing defects, it ensures high cost-effective processing cycle, low cost consumption and high productivity.

In addition to chromium coating, it can also be plated with silver, providing a very wide range of design options and design color diversity in terms of color and effect.

Diamond like carbon (DLC) coating is often used in automobile engine to reduce the friction of engine. The black color makes DLC coating popular as decoration coating (such as watch). Because of its low friction and non adhesion coefficient, DLC coating is well used in tool coating. DLC coating technology is very suitable for machining and casting / forging, as well as coating of aluminum and plastic injection mold.

DLC coating technology:

Different types of diamond-like carbon coatings have different production technologies. DLC coating is suitable for extreme wear and high relative speed, even in the condition of no lubrication operation. It has excellent wear resistance, anti-oxidation and adhesion (anti-wear). It can withstand the surface pressure that will immediately lead to wear and cold welding under normal conditions, reduce the friction loss to the minimum, and good corrosion resistance can prevent the matrix from damaging attack.

HCVAC applies its long-term experience in carbon based coating process and vacuum coating equipment technology to metal bipolar plates of fuel cells. Good results in adhesion, conductivity and corrosion resistance have been obtained by plasma surface cleaning and special bonding layer in the coating cavity.

The company mainly provides metal bipolar plate coating equipment to the market, and can provide coating materials according to customers' needs, including graphite and precious metals. The cost value of small batch experimental production equipment and mass production is very consistent with the industrial route.

HCVAC antibacterial coating combines the strength, durability and beauty of PVD coating, and has excellent antibacterial performance. Its antibacterial properties can inhibit the proliferation of pathogens that may infect the surface. All daily articles that may contact people need this type of coating.

Thanks to the innovative coating process developed by HCVAC, the antibacterial coating can not only completely inhibit the growth of bacteria, but also eliminate them to ensure the complete sanitation of the surface.

The precise laboratory tests prove that this antibacterial efficiency is caused by the nano embedding in the complex structure of the multilayer coating, which destroys the bacterial cell membrane by blocking its nutrition and interrupting the cell division cycle.

Antibacterial and antiviral effects

Due to the physical properties of the coating, the antibacterial effect continues throughout the life of the object and improves over time.

Thanks to its antiviral effect, it is a completely hypoallergenic product. In addition, according to DM 3/21/1973 test, the coating is completely safe for human contact.

Antibacterial color and substrate

The antibacterial properties of HCVAC antibacterial coating combine with the aesthetic quality of PVD coating: hardness, UV resistance, high color stability and scratch resistance.

Antibacterial coatings can be applied to many different types of substrates: ferrous and non-ferrous metals, polymers such as ABS and polycarbonate (with appropriate pre-treatment).

Laboratory testing

The efficacy of HCVAC antibacterial coating has been tested against the bacteria of Escherichia coli (Gram negative) and Staphylococcus aureus (Gram positive) strains. These two bacteria belong to the popular bacteria family that are most responsible for "contact infection", and have achieved excellent results on newly produced samples and products that have been used for a long time.

Thermal barrier coating is a key technology for the development of advanced aero-engine and ground gas turbine. It is composed of ceramic surface layer with excellent thermal insulation performance and metal bottom layer with bonding function. It can avoid the direct contact between high-temperature gas and metal matrix, effectively protect the matrix, prolong the working life of engine and improve combustion efficiency.

Ps-pvd realizes large area and uniform physical vapor deposition by rapid thermal spraying. By changing the plasma jet state, ps-pvd can also realize the deposition of multiphase composite coatings, and expand the design and preparation of thermal barrier coatings with different microstructure. More importantly, the plasma jet of ps-pvd has good coating ability, which can realize the deposition of non line of sight thermal barrier coating on the surface of complex workpiece.

Lidar is widely used in driverless and UAV fields. Lidar system includes a single beam narrow-band laser and a receiver. It can be seen that narrow-band filter plays an important role in lidar and will be more widely used in the future.

Lidar is a radar system that detects the position, velocity and other characteristics of the target by emitting light beam.

Equivalent to our eyes, it has strong and complex information perception and processing ability.

Excitation light radar has been widely used in aircraft obstacle avoidance, reconnaissance imaging, missile guidance and other fields for many years.

IR-cut filter for lens refers to the infrared light that can be filtered in front of semiconductor photosensitive element (CCD or CMOS) to make the reproduction color of lens image consistent with the actual color. The most commonly used is the 650nm cut-off filter.

▶ Remove unwanted ultraviolet and infrared light!

Point:

● Reflect ultraviolet and near-infrared emitted from a lamp and permeate the visual spectrum.

● Moire and near infrared light are to be removed by this coating.

● It is used to prevent degradation due to malfunction of stray light or ultraviolet.

● The performance of this coating relies on the quality of low-particle, high-transparency and low-Haze.

At present, AR film is mainly used in telescope, glasses, digital camera lens, LCD projection system, optical window, protective mirror, notebook, computer, mobile phone, TV, glasses, touch screen, etc.

Structurally, AR film can also be divided into single-layer antireflection film and multi-layer antireflection film:

Single layer antireflection film in order to reduce the reflected light on the surface, the simplest way is to coat a layer of low refractive index film on the substrate surface.

Multilayer antireflection film is called multilayer ar film when more than two layers of reflective materials are plated on the film. Multilayer has better performance than single layer.

AF / as coating, namely antifouling film (as) and anti fingerprint film (AF film), mainly deposits organic fluoride materials on various glass or plexiglass PC, PMMA, pet and other substrates through vacuum coating technology, so that the substrate surface has the functions of waterproof, oil, scratch, fingerprint and stain prevention.

Hydrophobic coating is a new progress, which can be added to our coated glass to form waterproof optics. The hydrophobic coating is combined with the glass to form a barrier against dirt, dust, grease and liquid. The coating is non acidic. It allows the use of rags to clean the glass without using cleaning solution. This kind of waterproof glass coating is very suitable for touch screen.

It is widely used in digital products, watches, hardware and other glass, metal, plastic, ceramic panels, part surfaces, and decorative and functional films. It is coated with AF and as coatings to improve surface hardness, smoothness, wear resistance, chemical resistance and easy cleaning.

AS / AF film test standard:

■ the initial contact angle range is 115 ± 5 °;

■ friction resistance test standard of steel wool: use 0000# steel wool with an area of 10 * 10mm, travel 40 times / min, load 1kg, and contact angle greater than 100 ° after 5000 round-trip friction;

■ eraser test standard: 6mm diameter eraser, stroke 25 times / min, load 1kg, contact angle greater than 100 ° after 2500 round-trip friction;

Remarks: the test sample glass shall be the special glass for the touch screen cover plate after precision polishing, and the surface shall be smooth.

Compared with traditional magnetron sputtering, ICP sputtering optical coating adopts metallization sputtering first, and then reacts with metal film through ionization reaction gas to synthesize dielectric film. Its process cavity always maintains vacuum in a PM (maintenance) cycle, providing a stable and reliable coating environment and higher production efficiency. It is suitable for plating AR, superhard AR, bbar film, mirror, ncvm, filter and other optical films on the plane or curved surface of glass, plastic and other substrates. It can also realize the plating of AF / as film. ICP source is used for substrate cleaning and auxiliary deposition in evaporation / sputtering process:

Electron gun auxiliary: it can pass a variety of gases. In addition to auxiliary, some applications can be protected by a layer of DLC after plating;

PVD auxiliary: mainly used for oxygen and nitrogen supplement applications, suitable for oxides and nitrides. In the case of high-speed sputtering with metal target, the ICP source is used to supplement oxygen or nitrogen for oxidation or nitridation, so as to realize the rapid preparation of high-precision optical films by magnetron sputtering.

Advantages of ICP:

Increase the plasma density, especially the ionization rate of inert reaction gas

High energy particle bombardment to improve the film density

Improve the film-forming quality and avoid high-temperature process

Change the crystal structure of the film to change the chemical or electrical properties of the film

CCP capacitively coupled plasma

The principle of capacitance coupled plasma is different from that of inductively coupled plasma. Capacitive coupling is made of grounded discharge chamber (made of materials with small composite coefficient, such as quartz) and introduced drive electrode as coupling element. The driving electrode is plated with ceramic materials with low sputtering yield to reduce the sputtering of ions on cathode materials. When connected to the power supply, a high-frequency electric field is generated between the discharge chamber and the drive electrode, under which the free electrons move up and down, and discharge is excited. Since the free path of electrons is much larger than the size of the discharge chamber, they are multiplied mainly by the secondary electrons they knock out of the tube wall. The latter becomes the maintainer of this discharge, and the secondary electrons generated by gas ionization will play a secondary role.

RF ion source

Provide a wide and uniform ion beam source for reactive processes, such as ion beam assisted deposition or ion beam deposition of highly controlled optical coatings.

Reliable and consistent operation in inert and oxidizing environments.

Stable and efficient plasma gymnastics has precise control ability and allows high repeatability.

It is very suitable for load locking production process.

Electrodeless discharge, long service life, long working time and stability.

The working height is up to 1m.

The ion energy and ion beam current density can be accurately controlled and vary widely.

Hall ion source

It is designed to provide high beam current for vacuum coating process, so as to improve process uniformity and prevent substrate damage, and realize surface pre cleaning, auxiliary deposition and selective etching.

It is very effective for applications requiring high current and low energy ions.

High beam current is particularly useful for controlling film stress and stoichiometry.

Ion energy divergence, ion beam divergence, with large uniform area.

Low ion energy and high ion beam density.

The utility model has the advantages of simple structure and convenient disassembly.

kaufman ion source

Ion energy and beam density can be accurately controlled without being affected by the environment.

Small amount of bleeding and less pollution.

The working temperature rise is low and can be cold plated.

The unique frequency measurement system provides stable and high-resolution rate and thickness measurement, giving excellent repeatability to the monitoring process. Through the deposition controller, the QCM sensor can be used to control the deposition rate. Huicheng vacuum can provide you with any deposition controller with the most basic to the most complete functions according to your requirements.

Even in the case of extremely low rate, it can ensure the highest and most stable rate and thickness measurement resolution. By automatically measuring the ratio of deposited materials, it can improve the accuracy of thickness measurement and support simultaneous co deposition from multiple sources. The USB data storage function can store screen shots, formula storage and data recording.

Through the optical film thickness monitor, you can extremely accurately control the deposition speed and thickness, can reach almost any number of layers, easy installation and high reliability, so as to ensure production efficiency. Huicheng vacuum provides an instrument with extremely low cost of ownership and brings you unprecedented value. Whether your control needs belong to the field of production or R & D, you can find a perfect solution from the optical film thickness monitor.

Founded in 2006, we are a supplier of vacuum application solutions focusing on the R & D, production, sales and technical services of vacuum coating equipment. Our main products are vacuum coating equipment and supporting process service support. After years of technical development and experience accumulation, it has complete R & D and manufacturing capacity of vacuum coating equipment and coating process development capacity, and provides customized and professional vacuum coating equipment and process solutions for customers in different industries. Successfully listed on the Shenzhen Stock Exchange's Growth Enterprise Market (GEM) in June 2024.

Decorative pvd coating machine/Decorative vacuum coating machine

Optical pvd coating machine/Optical vacuum coating machine

Functional pvd coating machine/DLC coating machine

Web coating machine/roll to roll coating machine

Automotive pvd coating machine/Automotive vacuum coating machine

Add : No.2 Longyuan Road,Yanwu,Dalingshan Town,Dongguan City,Guangdong Province,China

Tel :+86-769-85611173

E-Mail :info@hcvacuum.com

WhatsApp :+86 133 1668 9188

Http : www.hcvacuum.com