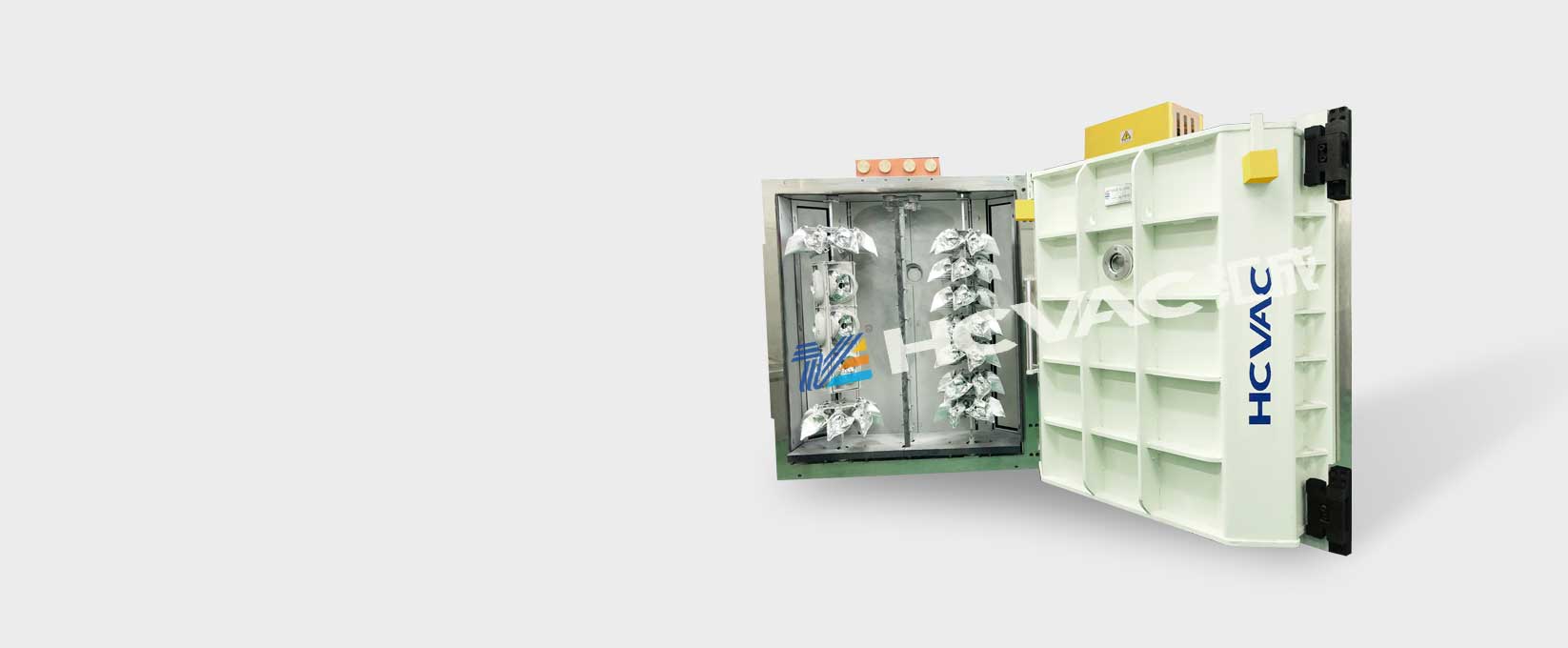

Two Axis Automotive Lighting Coating Machine

Plasma enhanced chemical vapor deposition (PECVD) is used for the combination of sputtering and thermal evaporation reaction of anti-corrosion metal layer on reflective and decorative surfaces. The further application is reactive magnetron sputtering. The surface engineering of transparent layer, such as wiping layer and easy cleaning layer (with lotus leaf effect), is the highest reflectivity of automobile rearview mirror and silver layer stack.

The main functions of HCAL series machine include: high pressure ion bombardment, aluminum plating and super hard protective film (SIO) coating in vacuum chamber at one time. The superhard protective film improves the nitriding resistance of the aluminum layer and keeps the high reflectivity of the aluminum layer for a long time. The coating of automobile lamp, train lamp, motor car lamp, truck lamp, electric car lamp, bus lamp, military lamp, racing car lamp, school lamp, bicycle lamp has reached the national standard of automobile lamp, and has passed the experiments of acid, alkali and salt resistance. The computer is used to control and monitor the running state of the machine and the coating process. It improves the work efficiency, ensures the stability and consistency of product quality, and reduces the influence of human factors.