Functional film coating machine

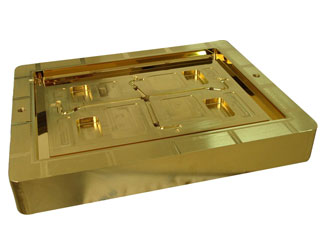

HCVAC developed PMA II patented technology on the basis of PMA I technology, and successfully integrated PMA II into a new generation of coating system. The system has flexible configuration and can be combined with ARC, MS, HIPIMS and other technologies to provide more possibilities for the development of new coatings and new materials. It provides a complete coating solutions for tool coating, mould coating, parts coating, DLC coating, GLC coating, ta-C coating, etc.

It is widely used in scientific research, semiconductor, tools, molds, parts and components, medical devices, optical, new energy and other industries. It can deposit AlTiN, TiAlAlN, AlTiXN, AlCrN, AlCrXN, TiSiN, CrN, TiN nitride coatings, Ta-c, graphite-like, Cr+a-c, Cr+a-c:H, W+a-c:H and other carbon substrates, Cr+a-c:H, CrN+a-c:H PECVD coatings.

HCVAC provides the most advanced PVD, PACVD and other functional coatings for high speed steel and cemented carbide workpieces to meet various processing requirements and workpiece materials.

HCVAC coatings save overall machining costs because they allow higher cutting speed, feed and reduced tool change time due to longer service life. The low friction and hardness of the coating allows for reduced lubrication and cooling, establishes predictable wear, and ensures better surface quality of machined parts.

High performance coatings:

High performance coating is a tool specially designed for high speed and large feed processing of tough and rough workpiece materials with high heat and mechanical load, minimum or low lubrication and cooling.

Coating value:

Many special applications of coating processing in HSS and cemented carbide workpieces are important parts for cutting metals, plastics, composite materials and other materials including wood. They provide high efficiency, extend the service life of the workpiece and reduce the overall cost.

| Main modules | |

| Arc | HiPIMS |

|

The innovative APA evaporator technology (Advanced Plasma Assisted) is based on cathodic vacuum arc and offers diverse development possibilities for new layer architectures. Benefits: ●High target utilisation result in low target costs ●High deposition rates ●Adjustable magnetic fields ●Short target changing times ●High plasma density ●Reduction of macro-particles ●Excellent coating adhesion |

HiPIMS stands for High-Power Impulse Magnetron Sputtering. Benefits: ●High ionisation rate (similar to arc) ●High power densities from 100 to 1000 W/cm2 ●Very high plasma density ●Layer structures adjustable by plasma parameter settings ●Very smooth coatings ●Excellent coating adhesion ●Deposition of dense coatings at low substrate temperatures |

| Additional modules | |

| Sputter | Nitriding |

|

In the sputtering process, atoms are extracted from a target by bombardment with high-energy ions (Ar) and transformed into the gas phase. By combining the sputtered material with additional gases, a coating is deposited on the substrate. Benefits: ● A wide range of materials can be sputtered ● Diverse process variants available ● Smooth coatings ● Good coating adhesion on combination with power etching prozess AEGD |

With the nitriding module, a plasma nitriding process can be performed before a PVD and/or PACVD coating process in one system and one batch. Thereby a hardened layer can be produced which offers excellent support for the subsequent PVD/PACVD coating. Benefits: ● Optimisation of tool and component properties ● Substitution of expensive base materials ● Significantly longer lifetimes ● All PVD coatings can be applied |

| DLC | ta-C |

|

DLC stands for Diamond-Like Carbon and refers to a group of extremely low friction amorphous carbon coatings. With the DLC module, different DLC coatings can be produced by using PVD and/or PACVD processes. Standard DLC coatings consist of metal free or metal containing carbon coatings. Benefits: ● Excellent coating adhesion ● High wear resistance ● Low coefficient of friction ● Smooth coatings |

ta-C stands for tetrahedral amorphous carbon without hydrogen and refers to a group of extremely hard and low friction amorphous carbon coatings. With the ta-C module different ta-C coatings can be produced. Benefits: ● For higher temperature environments than DLC ● Very high wear resistance ● Excellent coating adhesion ● Smooth coatings |