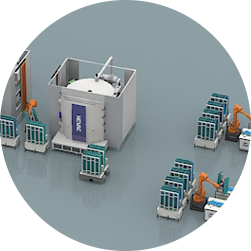

Multicavity magnetron sputtering optical coating machine

Compared with the ordinary plane target device in the industry, the service cycle and utilization efficiency of the target material of the rotating cathode device are significantly improved; the customized structure of the base plate workpiece frame can provide the maximum utilization space for the customer's product placement; the fully automatic lifting and lifting frame device can greatly reduce the opening and closing time of the machine and greatly improve the production efficiency and process stability; the patent separation The sub source has the characteristics of wide energy balance, high isolation rate, super stable working efficiency and low energy consumption.

It can use time to precisely control the film thickness, meet the design process requirements, save crystal control and optical control links, and save a large number of film thickness instrument consumables for customers; it can produce high refractive index nitriding film, improve the film hardness performance; it can be used for various purposes at low temperature; it can automatically adjust the gas flow patent device, maintain a stable target voltage, and ensure the film quality; optional "correction plate" External adjustment mechanism ".

The sputtering deposition system is equipped with a plurality of cylindrical targets on the side wall to improve the deposition rate and multilayer coating. The system is equipped with a DC pulse or RF power circular cathode. The vertically mounted substrate and cylindrical cathode can minimize the particle pollution in the coating process.

AR ilm (substrate glass transmittance > 91.5%):

■ In 420-680nm band, the average transmittance of one side is more than 95%, and the reflectivity is less than 0.5 (average);

■ The average transmittance on both sides is more than 98%, and the reflectivity is less than 0.5 (average);

Color film or gradient film:

■ According to the customer's sample, five furnaces are loaded at random or full, and the color difference Δ E & lt; 1.2;

■ Boiling test: boiling at 80 ℃ for 30min, 3M after 100 grid test (1 * 1mm), it is more than 4B.