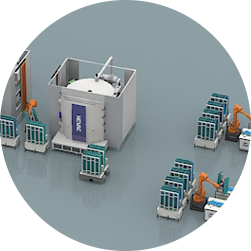

Impedance evaporation AS optical coating machine

AF / AS coating, i.e. antifouling film (AS) and anti fingerprint film (AF film), is mainly to deposit the organic fluoride material on various glass or organic glass PC, PMMA, pet and other substrates by vacuum coating technology, so that the surface of the substrate has the functions of water-proof, oil-proof, scratch proof, fingerprint proof, stain proof and so on.

Hydrophobic coating is a new progress, which can be added to our coated glass to form a waterproof optical device. Hydrophobic coating combines with glass to form a barrier against dirt, dust, grease and liquid. The coating is non acid. It allows the use of rags to clean glass without the use of cleaning fluid. This kind of waterproof glass coating is very suitable for touch screen.

Widely used in digital products, watches, hardware and other glass, metal, plastic, ceramic material panels, parts surface, and decorative and functional film plus AF, AS coating, improve surface hardness, smoothness, wear resistance, chemical resistance and easy cleaning.

AS/AF membrane test standard:

■ The range of initial contact angle is 115 ± 5 °;

■ Friction resistance test standard of steel wool: use 0000 × 10 mm steel wool, area is 10 * 10 mm, travel 40 times / min, load 1kg, after 5000 times of back and forth friction, contact angle is greater than 100 °;

■ Test standard of eraser: 6mm diameter eraser, 25 strokes / min, 1kg load, 2500 round-trip friction, contact angle greater than 100 °;

Note: the test sample glass shall be the touch screen cover plate special glass after precision polishing, with smooth surface.