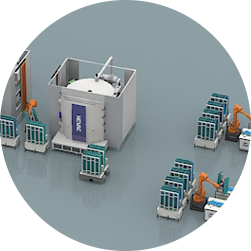

High precision E-beam evaporation optical coating machine

The precision vacuum coating machine for forming high precision optical multilayer film on glass / PC / PMMA substrate; the combination of various components to meet the customer's needs can form the film with better quality; the umbrella frame of substrate adopts the central rotation mode to reduce the vibration and particles, so that the substrate can rotate stably.

The multi-layer film can be stably formed by using the electron beam heating method without electrode on the crucible as the evaporation source; the high-precision and stable optical multi-layer film can be formed by adopting the unique ratio control method and multi-point online monitoring of the company; the base umbrella frame can be taken out by using the elevator with good operability.

Using the ion source with uniform distribution and high ion current density, equipped with double electron guns, the multi-point and ring crucible can be plated with more than 100 layers. The automatic evaporation process is realized by using the automatic evaporation control system, and the workpiece frame can be bell type or planetary type.

AR ilm (substrate glass transmittance > 91.5%):

■ In 420-680nm band, the average transmittance of one side is more than 95%, and the reflectivity is less than 0.5 (average);

■ The average transmittance on both sides is more than 98%, and the reflectivity is less than 0.5 (average);

AS/AF membrane test standard:

■ The range of initial contact angle is 115 ± 5 °;

■ Friction resistance test standard of steel wool: use 0000 × 10 mm steel wool, area is 10 * 10 mm, travel 40 times / min, load 1kg, after 5000 times of back and forth friction, contact angle is greater than 100 °;

■ Test standard of eraser: 6mm diameter eraser, 25 strokes / min, 1kg load, 2500 round-trip friction, contact angle greater than 100 °;

Note: the test sample glass shall be the touch screen cover plate special glass after precision polishing, with smooth surface.