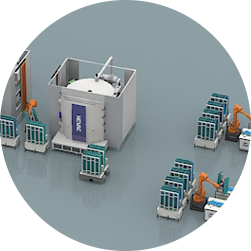

Large E-Beam optical coating machine

Equipped with electron gun, cavity type, waist type or ring crucible, impedance type evaporation source; equipped with optical film thickness controller or quartz crystal film thickness controller, it can realize automatic control of film forming speed and coating process; optional RF / Kaufman / hall type ion source.

The development of the series is to meet the market demand for large-scale production. The machine has been verified by production, with high productivity and the lowest cost of ownership. The cost of mass optical elements is optimized. AR, UV / IR cut-off filter, AF, hard film, decorative film, ITO film, band-pass filter, HR film can be prepared.

AR ilm (substrate glass transmittance > 91.5%):

■ In 420-680nm band, the average transmittance of one side is more than 95%, and the reflectivity is less than 0.5 (average);

■ The average transmittance on both sides is more than 98%, and the reflectivity is less than 0.5 (average);

AS/AF membrane test standard:

■ The range of initial contact angle is 115 ± 5 °;

■ Friction resistance test standard of steel wool: use 0000 × 10 mm steel wool, area is 10 * 10 mm, travel 40 times / min, load 1kg, after 5000 times of back and forth friction, contact angle is greater than 100 °;

■ Test standard of eraser: 6mm diameter eraser, 25 strokes / min, 1kg load, 2500 round-trip friction, contact angle greater than 100 °;

Note: the test sample glass shall be the touch screen cover plate special glass after precision polishing, with smooth surface.