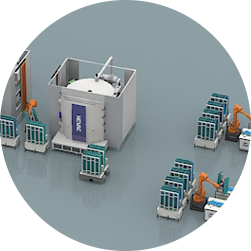

Optical thickness monitor Accurate control of deposition rate and thickness Optical thickness monitor

The unique frequency measurement system provides stable, high-resolution rate and thickness measurement, and gives the monitoring process excellent repeatability. Through the deposition controller, QCM sensor can be used to control the deposition process. Huicheng vacuum can provide you with any deposition controller with the most basic and complete functions according to your requirements.

Even in the case of extremely low speed, it can ensure the highest and most stable speed and thickness measurement resolution. By automatically measuring the ratio of deposited materials, the accuracy of thickness measurement can be improved, and multiple sources can be co deposited at the same time. USB data storage function can store screen section, formula storage and data record.

Through the optical film thickness monitor, you can control the deposition speed and thickness extremely accurately, can reach almost any number of layers, easy installation and high reliability, thus ensuring production efficiency. Huicheng vacuum provides a very low cost instrument, which brings you unprecedented value. Whether your control needs to belong to the field of production or research and development, you can find the perfect solution from the optical film thickness monitor.