Flexible electronic roll to roll vacuum coating machine

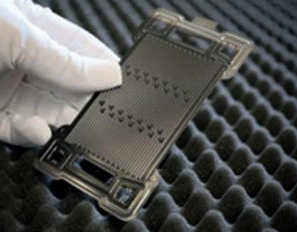

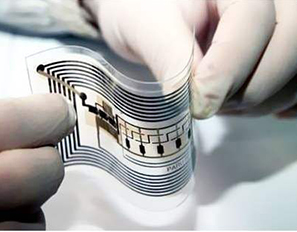

HCFLC series of winding and coating machine provides a highly competitive and cost-effective film coating technology for a variety of flexible and wearable electronic products, sensors, RFID tags, intelligent glass, intelligent packaging, etc. The application of high quality and low resistivity copper or TCO layers and structures has successfully closed the gap between productivity and versatility while meeting today's and future market demands.

HCFLC series is the best choice for production and R & D. Almost unlimited possibilities in arranging up to six groups of rotatable rotators and machines, the application of a large number of on-site measurement sensors enables the machine to be produced in a production environment while being very flexible and flexible when used as a research and development machine.

This also makes the machine the first choice for applications such as ITO film, FPCB, Low-E or smart glass. The rotatable magnetron, with a maximum coating width of 2000 mm and a possible substrate roller diameter of 500 mm, is the basis for high productivity. In addition, optional gas separation between adjacent process sections allows deposition of various metal and dielectric layers in one process.

In addition to being able to operate the reactive sputtering process simultaneously with the non reactive sputtering process, the hcflc series can also be equipped with various in-situ sensors for continuous and accurate monitoring of the required physical layer properties, such as layer resistivity, reflectivity or transmittance.