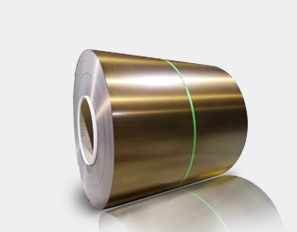

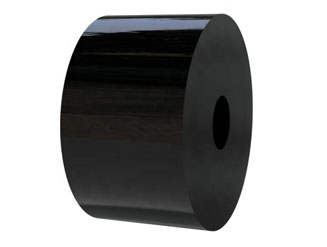

Metal strip web coating machine

HCMRC series machine adopts the combination of magnetron sputtering coating technology, cathode arc ion coating technology and specially designed ion source assisted deposition coating technology developed by the company. It has been successfully applied in large diameter, wide width and high vacuum continuous winding coating machine. Decorative film and anti-corrosion coating can be plated on both sides, improving the surface characteristics of metal coil and expanding the application range.

Modular design concept, flexible combination of strip correction system, plasma pretreatment, magnetron sputtering system, on-line measurement and process control system, electron beam evaporation. It is the best choice for continuous coating production line of large stainless steel coil with good uniformity, high deposition efficiency and fast coating speed.

The modular design is a flexible production tool for thin film coating. Through our unique combination of various technologies, we can produce high reflection film, high absorption film and decorative coating. In addition, for more extensive application, we can also deposit anti touch coating or anti-corrosion coating.

Decorative coating

◆ With the lowest process cost, the material surface has high-quality metal texture. Both surface color layer and interference color layer can form a wide range of different colors.

Anticorrosive coating

◆ PVD technology is used to effectively steam zinc or magnesium on the front and back sides of the steel strip to improve the corrosion resistance.