Holographic anti counterfeiting web vacuum coating machine

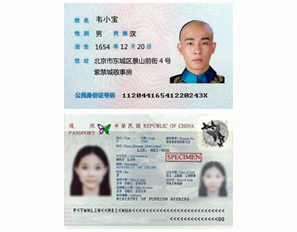

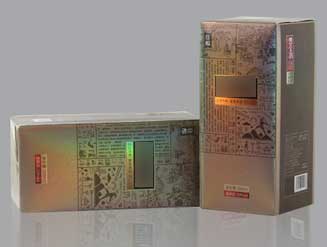

Every day, millions of people present their passports while traveling, security cards at work, or pay in cash or credit cards. Modern security systems ensure that these cards and documents are tamper proof. Making security labels for these applications is a very complex and complex process. In general, it requires several separate processing steps. For the deposition layer, special solution is needed to ensure high precision, high quality and reproducibility. The hcsec family of devices provides the right platform and technology for these products and successfully combines the corresponding productivity with the required flexibility.

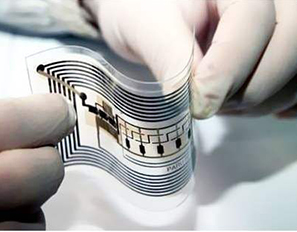

HCSEC series machine is a roll to roll coating machine for protection, safety and optical effects in large quantities on pet and (b) OPP substrates. Two different evaporators are used for different materials to minimize flexibility while reducing installation time. Layer deposition is based on thermal evaporation. Aluminum, silver and zinc sulfide are the most commonly used coating materials.

In the vacuum state of 9.9 × 10-2Pa, the aluminum wire or medium is vaporized by heating high frequency, resistance or electron beam, so that the metal aluminum atoms or non-metallic medium molecules are uniformly attached to the surface with optical information pattern, and then cooled and solidified. The optical information recording layer on the film is coated with a layer of about 350 a in thickness, which can increase the barrier performance of holographic medium to air and sunlight, and protect the information layer.