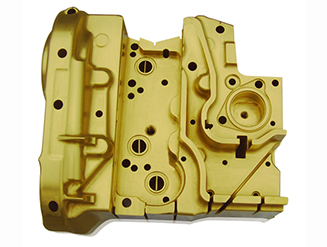

The die casting industry is constantly finding itself facing new challenges in terms of die casting part tolerances and cycle times. HCVAC coating equipment plating super hard, extremely corrosion-resistant and wear-resistant coating is an important factor to protect mold from welding and premature fire crack. The maintenance cost and scrap rate are greatly reduced. Therefore, the coating has made a valuable contribution to reliable die casting process and ensured product quality and productivity.

The coating of HCVAC coating equipment can protect die casting die, die insert and core from premature wear. Depending on the complexity of the casting and the alloy used, up to 280000 sheets can be processed at one time. It can reduce welding, delay fire crack, reduce erosion, reduce wear, reduce scrap, prolong service life, reduce maintenance cost, reduce demoulding force and best surface quality.