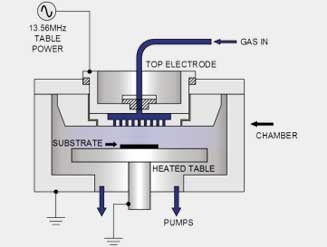

PACVD is the abbreviation of plasma assisted chemical vapor deposition. Sometimes it is also written as PECVD. E stands for enhancement. In the PVD process, the coating material is obtained by evaporation from the solid form; in the PACVD process, the coating is obtained from the gas form, and the gas, such as hmdso (hexamethyldimethylsiloxane), under the action of plasma, is about 200% Non reactive gases, such as argon, can cause ions to deposit on the workpiece surface and form a very thin coating. Diamond like carbon (DLC) coating is a good example of PACVD technology, which is usually used in tribology and automobile industry.

Plasma assisted chemical vapor deposition (PACVD) is used to deposit DLC coatings. Chemical reactions in the process are activated by plasma excitation and ionization. With this process, we can use pulsed glow discharge or high-frequency discharge to deposit DLC coatings at about 200 ° C. the diamond-like carbon coatings produced by PACVD have low friction coefficient and extensible surface hardness.